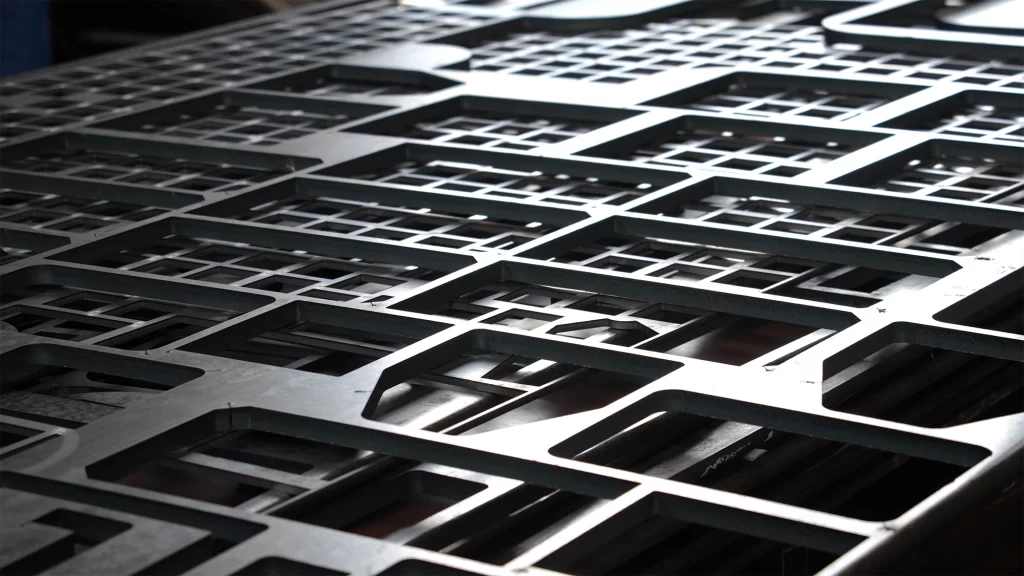

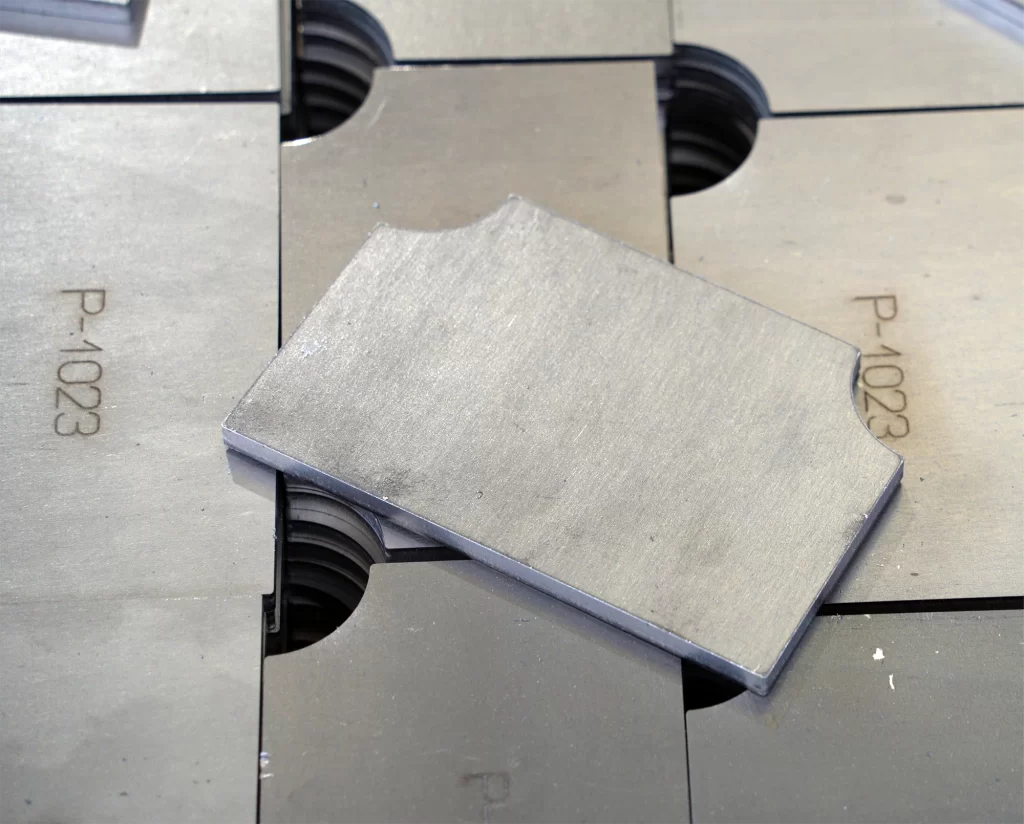

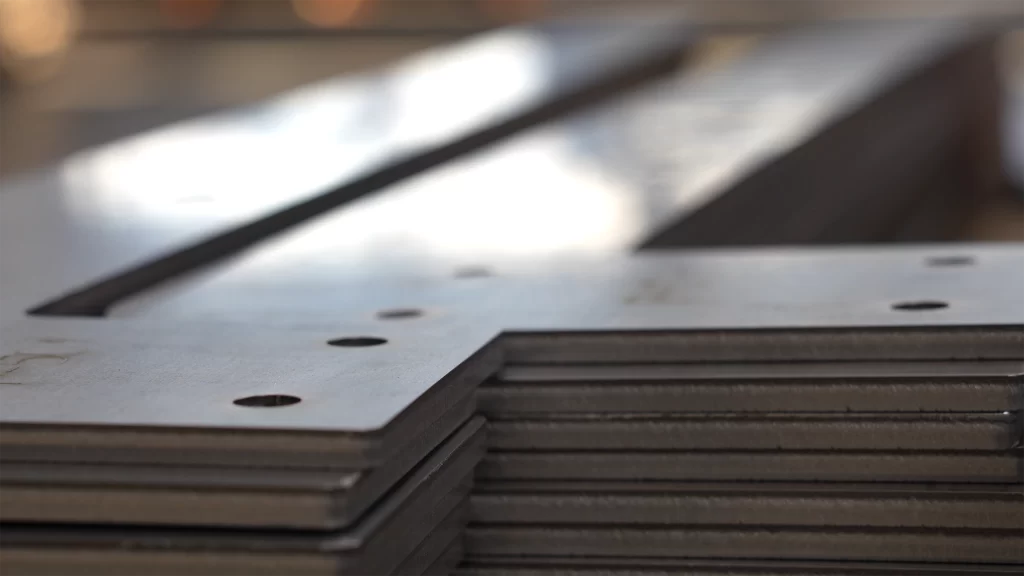

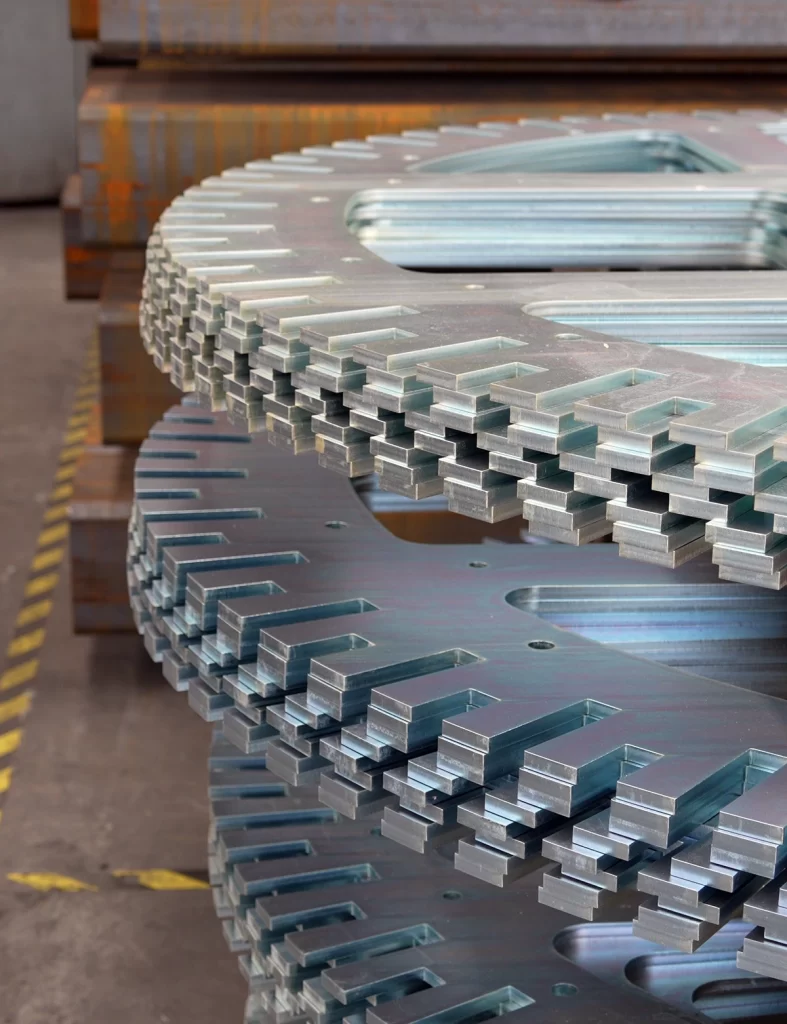

The best technologies are used to shape more than 7,000 tons of sheet metal each year, in various materials (carbon steel, stainless steel, aluminum)

The best technologies

Maximum precision

Reduction of processing times

Main technologies:

- 3D CO₂ laser cutting of closed and open profiles (steel and stainless steel max 100 kg/m)

- 2D CO₂ laser cutting 6,000 x 2,000 mm, 6,000 Kw

- 2D fiber laser cutting 6,000 x 2,500 mm, 12,000 Kw

- 3D plasma/oxyfuel cutting 28,000 x 3,000 mm

- Press bending department up to 8,000 mm

- Deburring and satin finishing

- Closed and open profile calendering and sheet metal calendering department

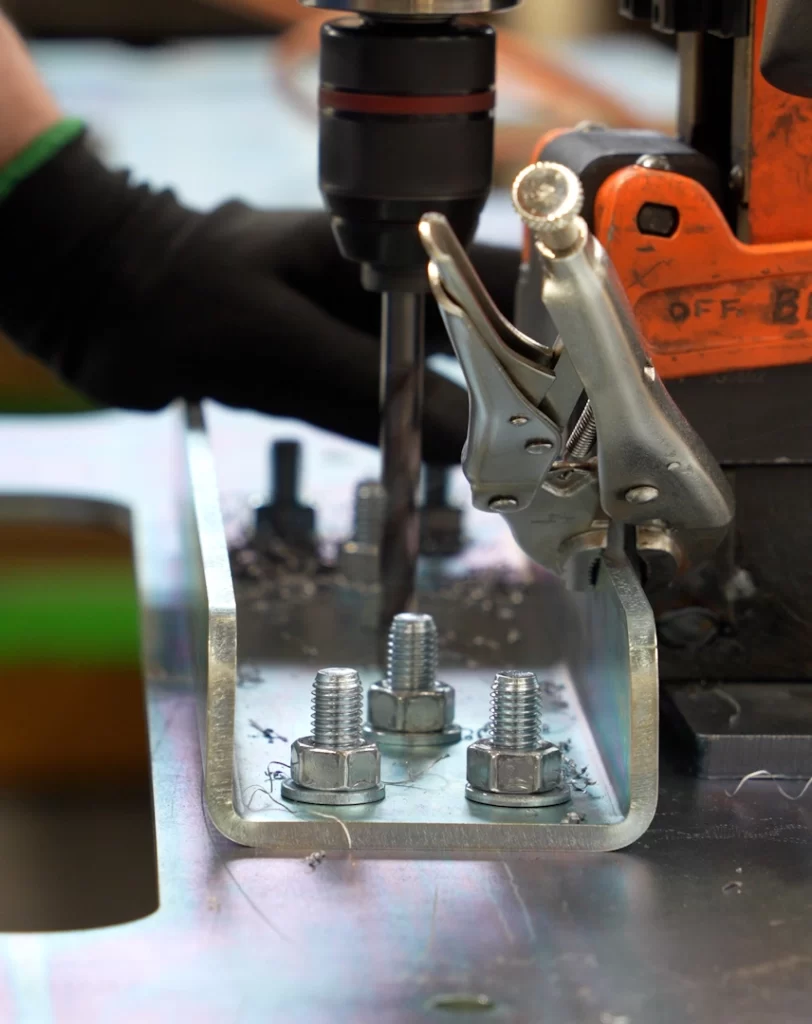

- Cutting and drilling profiles up to 16 m

https://www.youtube.com/watch?v=JL_vuAuM4HM